Baking

STEAM PIPES DECK OVEN

Description

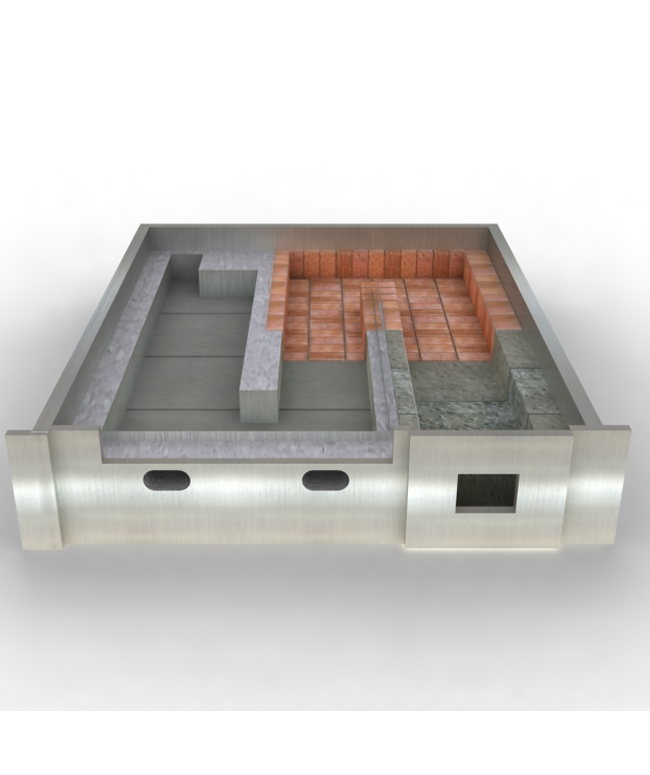

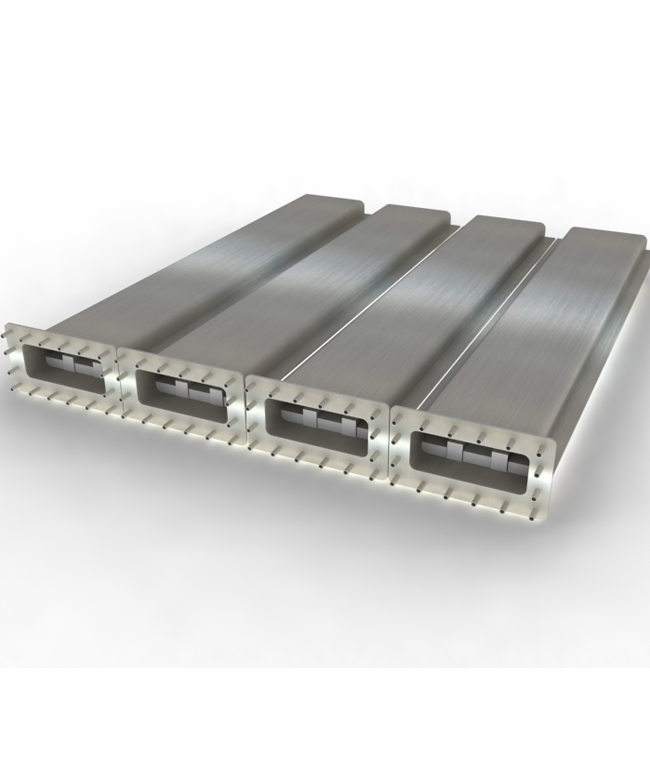

Tubix deck oven is a static oven with four overlapping baking chambers. The chief characteristic is the heating system: a dense network of closed circuit pipes in which steam circulates. These annular tubes that radiate the heat, wrap the baking chambers; therefore, the floor and ceiling that are in direct contact with the band of pipes, receive heat by conduction. Another key characteristic is the basement; made of refractory materials, it transmits the energy from combustions to the band of pipes, by granting a perfectly constant thermic performance.

FEATURES AND SPECIFICATIONS

- Heating system: network of closed circuit pipes.

- Overlapping baking chambers.

- Independent steam system for each baking chamber.

- Smoke ducts of refractory bricks.

- Perfect temperature recovery system.

- Balanced doors of tempered crystal glass and stainless steel.

- Removable doors, for easy cleaning.

- Efficient insulation system.

- Maximum baking temperature: 300°C.

- Time of continuous running: 24/24h.

- Mechanical or digital 24 volts panel.

- Available with gas or diesel burner; on request, fuel furnace.

BAKING QUALITY

- Optimal heat distribution.

- Bakes every product without adjustments.

- Excellent response to any baking requirement.

- The balanced airflow distribution throughout the pipes’ circuit grants:

Homogenous baking;

Excellent crust;

Excellent texture;

Maximized weight loss;

Maximized bread volume.

SAFETY DEVICE

- Automatic safety thermostat.

- Emergency push button. Steam exhaust fan.

- Door opens automatically in case of overpressure.

- Machine conforms to EU directives.

|

|

DECKS |

DOORS |

|

BAKING |

|

OUTSIDE |

CHAMBER DISTANCE FROM |

|

POWER |

|

WEIGHT |

||||||||

|

|

|

nr |

nr |

|

mq |

mm |

mm |

|

mm |

|

mm |

mm |

mm |

mm |

|

kw |

kcal/h |

|

kg |

|

420 |

|

4 |

2 |

|

7,90 |

1240 |

1600 |

|

1840x2870x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

65000 |

|

6500 |

|

421 |

|

4 |

2 |

|

9,90 |

1240 |

2000 |

|

1840x3270x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

80000 |

|

6900 |

|

422 |

|

4 |

2 |

|

11,90 |

1240 |

2400 |

|

1840x3670x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

90000 |

|

7300 |

|

330 |

|

3 |

3 |

|

8,90 |

1860 |

1600 |

|

2460x2870x2200+330 |

|

1000 |

1250 |

1500 |

|

|

1.4 |

70000 |

|

8500 |

|

331 |

|

3 |

3 |

|

11,20 |

1860 |

2000 |

|

2460x3270x2200+330 |

|

1000 |

1250 |

1500 |

|

|

1.4 |

85000 |

|

8900 |

|

332 |

|

3 |

3 |

|

13,40 |

1860 |

2400 |

|

2460x3670x2200+330 |

|

1000 |

1250 |

1500 |

|

|

1.4 |

95000 |

|

9300 |

|

430 |

|

4 |

3 |

|

11,90 |

1860 |

1600 |

|

2460x2870x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

90000 |

|

9700 |

|

431 |

|

4 |

3 |

|

14,90 |

1860 |

2000 |

|

2460x3270x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

120000 |

|

10100 |

|

432 |

|

4 |

3 |

|

17,90 |

1860 |

2400 |

|

2460x3670x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

135000 |

|

10500 |

|

441 |

|

4 |

4 |

|

19,80 |

2480 |

2000 |

|

3080x3270x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

140000 |

|

10900 |

|

442 |

|

4 |

4 |

|

23,80 |

2480 |

2400 |

|

3080x3670x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

160000 |

|

11300 |

|

443 |

|

4 |

4 |

|

27,80 |

2480 |

2800 |

|

3080x4070x2200+330 |

|

850 |

1100 |

1350 |

1600 |

|

1.4 |

170000 |

|

11700 |