Accessories

TRAY

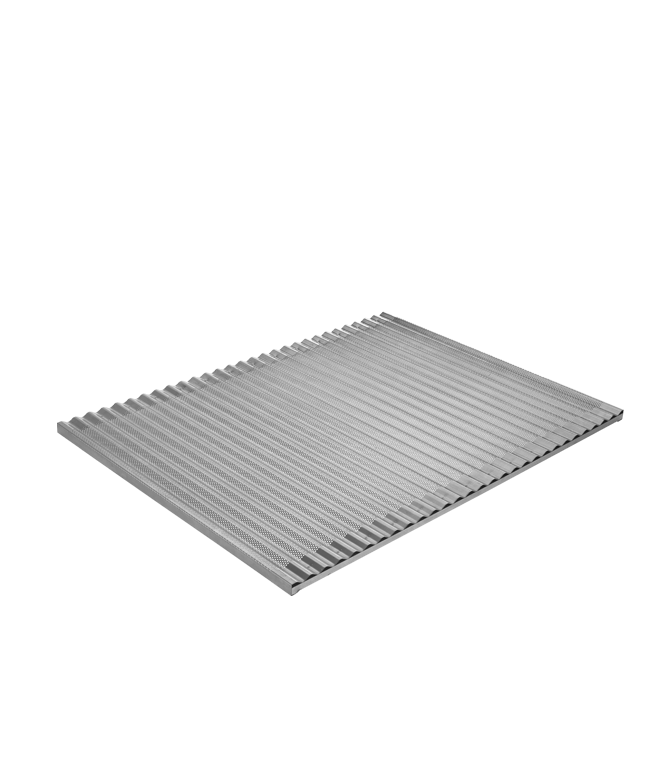

Description

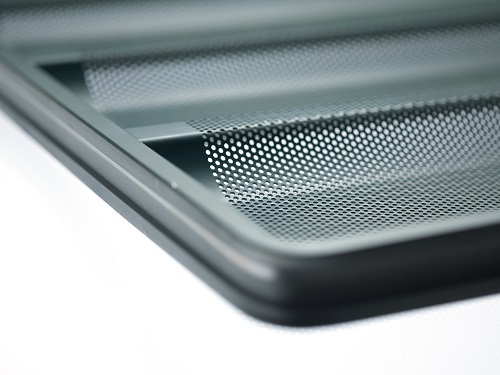

Our specific productive processes ensure high-quality baking trays that are suitable for both bakeries and confectionery use. The material is perforated, cut, folded and welded, its corners and edges - rounded, in order to avoid any risk, and the surface is suitable for easy cleaning and sterilization. The final products boast efficient technical solutions, convenience and practicability that optimize the baking process.

The total control over the production’s cycle and our up-to-date equipment grant different chances:

- Baking trays different in size, thickness, length and width.

- Standard perforation with a 2-mm diameter and 3,5 mm pitch (perforation, on request)

- Baking trays with 2,3 or 4 turned down edges.

- Turned edge with from 1 mm high and 30 and 120 mm angle range.

- Corrugated baking trays

- Channels number on request (minimum diameter: 20/22 mm)

CARE AND MANTINENCE

Do not:

- Do not clean by using sharp or abrasive equipment.

- Do not clean under high pressure (more than 5 bars).

- Do not use alkaline, aggressive products or solutions that are not suitable for food products.

- Do not heat when the machine is empty.

- Do not drop or bang baking trays. Move them with care.

Do:

- Clean by using water (in dishwashers at 50°C max), with neutral PH agents.

- Wash under below 5 bars pressure.

- Dry baking trays before using them again.

- Keep the products in cleaned, dry and free-of-dust places.

MATERIALS FOR FOOD PRODUCTION

Baking trays and other equivalent equipment are suitable for handling food products as provided for by: 1935/2004 European Regulation; Presidential decree N° 777 23/08/1982; Legislative decree N° 108 25/01/1992; Ministerial decree 21/03/1973 and subsequent amendments; EEC 89/109; EEC 02/72.